Electromagnetic shielding: why and how?

Electromagnetic shielding is the practice of reducing the electromagnetic field in a space by blocking the field with barriers made of conductive or magnetic materials. Electromagnetic shielding that blocks radio frequencies and electromagnetic radiation is also known as RF shielding.

The shielding can reduce the coupling of radio waves, electromagnetic fields and electrostatic.

A conductive enclosure used to block electrostatic fields is also known as a Faraday cage.

The reduction depends much upon the used materials, its thickness, the size of the shielded volume and the frequency of the fields of interest.The material thickness determines which frequencies will be blocked to get in or out the Faraday cage. For low frequencies as 10kHz is a softsteel layer of 6mm needed to get a reduction of 80dB, but a frequency of 30MHz can be shielded by copper foil with a 0.03 mm thickness.

Used Materials in RF shielding

Copper

Copper based RF shields are easy to manufacture and form into preferred shapes. Its high conductivity feature makes it an efficient shield against RF.

Mu-metal

Mu-metal is a nickel iron soft ferromagnetic alloy with very high permeability, which is used for shielding sensitive electronic equipment against static or low-frequency magnetic fields (such as hard disks inductive proximity sensors).

Aluminium

Aluminium is a versatile component when it comes to RF shielding. It can be used as a foil to block low frequency radio fields or it can be integrated in the construction to offer a built-in shield against radio frequencies.

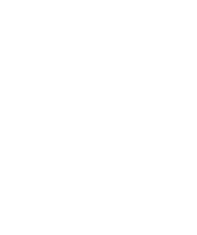

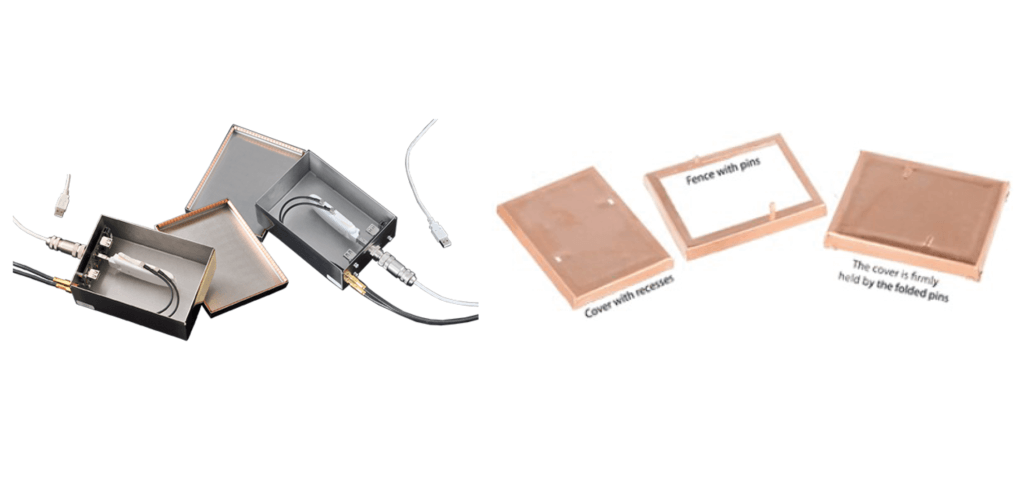

Figure 1: Examples of RF shielding. Source: qosmotec.com/Holland Shielding Systems BV

How to create an optimal EMI shielding

There are several ways to create an optimal EMI shielding:

- The RF part on the PCB will be shielded by a can.

- The complete PCB will be shielded by foils , wrappers or a box.

- Or the outermost housing is also shielded.

Shielding electronic goods housed in plastic enclosures can be done by coating the inside of the enclosure with a metallic ink or similar material. The ink consists of a carrier material loaded with a suitable metal, typically copper or nickel in the form of very small particles.